The pneumatic elements in the compressor that are found at the first place are the units that prepare the air. They are needed so that they may help in preparation of the working medium which are necessary for good operation of the pneumatic components. Clearing are the filtration which reduce the solid particles, condensed water and oil.

The reduction elements are used to adjust the pressure so that it can reach to the required level. The lubricators are used to reduce mist.

The preparation of compressed air is required so that the pneumatic components can be stable and the regulations and controls may extend their life. The reduction for the components failure may be achieved when the moving parts or the sealing have been lubricated.

The particulates enter the compressed air by the use of the compressor when it takes in the air found in its environment. They remain within a device where the compressed air stays such as the installation and pipes.

Such particles are then released by using the physic-chemical process like damaged seals, particle aging, scale and corrosion. They can also be removed mechanically when there are the moving parts found in the compressor and pneumatic components which had been included within a system.

The oil is found in the compressor especially in the piston and construction or it can be in a form of waste. It enters through the air flow on the ducts or on the walls. The oil is found in the form of the droplets and it can precipitate so that it can be condensate when there is pneumatic lubrication of oil mist done intentionally.

The water is found in the form of the vapor and it is sucked within the air compressor. The water may enter in the air tanks of the compressor.

The level of the water found in a working medium together with the air temperature leads to humidity. The filtration of compressed air happens within the filter which removes the particles. The filter has a certain element of the purification accuracy. The filter can also remove oil in larger particles.

The filter has to be built in the body that has the holes, exhaust and power. The air enters in a filter within the accordance of the arrow and it is directed downwards where there is the drive that cause the swirling of air steam and it expands and while doing this, it precipitates water found in the available air.

The oil separation is done by the oil separator. The condensate oil with the water is first removed by the filters but some remain in the air.

There are some industries where the air has to be free of the oil like in the medicine, varnishing, pharmaceutical and food. It is also not good for the automation of the industrial automation.

To have the best air for usage, the air has to pass through the pre-filtering where the air has to pass within the filters where the air is cleaned by getting rid of the concentrations of the oil particles. The filtration leads to the first class cleanliness and the filtration done by the activated carbon filter.

The drainage of the water from the compressed oil should be done through the filters at the first level but the remaining has to be done by the use of the dehumidifier which removes the water chemically and physically. This is the level that ensures that the air is completely prepared to work well.

The precipitated water found in the pneumatic system leads to many failures and disturbance. The water may lead to the corrosion and it reduces the active section of channeling element of the air and it increases air friction on the surface that had been corroded.

In order to reduce the pressure in any pneumatic system, there is a need to use the pressure reducers. Such valves are found in the group of the elements that control the pressure and they can be adjusted manually.

They have the task of maintaining the pressure at a constant level even if they may be higher inlet pressure even if there may be the changes in a rate of the flow within the valve.

These elements are found in the groups of these that have direct action or these that offer second control pressure which are the internal pressure of the references. The components are piezo valves or solenoid valves.

Lubrication

Lubrication of the pneumatic system is done on the elements and it is important when it comes to form friction of kinematic pairs. They may be pneumatic cylinders, piston rod and piston sleeve.

To ensure that the device is able to work in the proper way, it has to be lubricated by using oil. Lubrication of the air is also required for the pneumatic tools like grinders, screwdrivers, drills and hammer.

Lubrication in compressed air goes into the working system like oil particles or mist of oil and it reaches the cylinders and other moving parts and they also get lubricated. This helps to prevent the failures and the faults while it can prolong the life of the parts at the same time reducing the corrosion.

The lubricators are found in different types, they are vesicular, injection, wick, selection and drinkers. These that are common are known like the nipple lubricators. They are based on the system where the pressure drops within the lubricator gun nozzle and it draws some oil found in the reservoir using the droplet chamber through a tube.

The stream breaks the oil into the mist and it is then introduced within the pneumatic system.

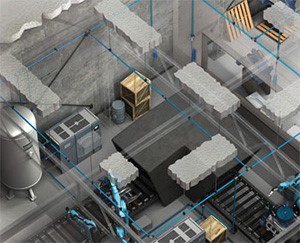

The air preparation elements at professional level are complex and they can include other additional equipment which are needed to be used in the pneumatic system.

They may be controlled manually or they can use slow start system. These elements can be pressure gauges, pneumonia-electric relays, solenoids and shut-off valves.

These actions lead to extend functionality of the normal units that use the air. The preparation elements can consist two piece service units which are filter-regulator with lubricator or three piece

Unit which includes the filter, the pressure reducing valve with the lubricator.