Stopping compressed air leakages is a simple way to keeping money in your wallet.

Unfortunately, some companies are still not aware of this and are underestimating the problem. Paradoxically, the reason for this is the money needed to detect and then eliminate leaks.

Sometimes, instead of spending money on generating future savings, one looks at current expenditures for a short time, because if they don’t spend on investments then the balance of the month will be positive.

Sometimes there are also different budgets in large plants. As a result, maintenance is not interested in generating savings for the company, as it will deprive them of their budget for repairing equipment or purchasing new tools.

These are of course extreme cases, because the subject of leak detection is as timely as possible and the awareness of users increases.

This time I will not discuss further leak detectors and I will pay attention to a rather ingenious product, which is a half-way solution to the problem.

Very often, after the work is finished due to leaks, the air is escaping and when in the morning we start working again, the air reservoir is empty. The compressor must therefore be inflated again, using energy.

Nothing at all, but by multiplying it by the number of working days in a month and later in the year, we will have a large amount of money for energy expenditure. It is worthwhile to turn the valve behind the tank after work is finished.

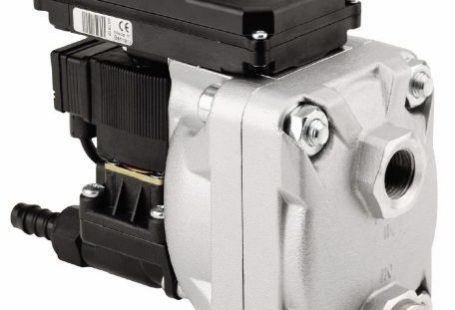

But what if someone forgets about it (nothing new;) or tanks are far away from workstations. Very interesting solution presents Jorc company by offering the automatic valve Air-Saver.

Please see how it works.

When the system is complete, Air-Saver disconnects the pressure tank from the rest of the system. This ensures that the air remains in the pressure tank and does not escape through leaks in the system.

The Air-Saver is installed at the compressed air outlet from the tank and can be programmed so that it opens automatically at the start of the shift and closes when work is complete. It can also be switched manually, of course.