Pneumatics comes from the Greek word and it means to breath. It is a part of the physics used in the technology which helps to use the pressurized air or gas. The pneumatic system that it is found widely within the industry is powered when using the compressed air and the compressed inert gas.

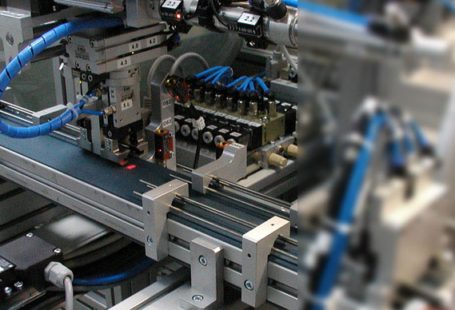

The compressors are electrically powered and they are found in the center to give power the air motors and cylinders with other types of the pneumatic devices. The pneumatic system which is controlled by the use of automatic or manual solenoid valve, it may be chosen if it is providing low cost or if it is flexible.

It can also be safer options compared to the actuators and the electric motors. The pneumatic is also used in mining, construction and dentistry among others.

Advantages of using pneumatic system

The pneumatic can be used on the air brakes, air compressors, air brakes, barostat, dental drill, gas operated reloading, HVAC control system, pipe organs, player piano, pneumatic actuator, pneumatic motor, pressure sensors and vacuum pump.

The pneumatic systems found in the fixed installation like the factories require using the compressed air since it is in sustainable supply and it can be gotten by compressing the air in the atmosphere.

The moisture is removed in the common air and oil in small quantity is added at the compressor so that there is no corrosion and that it lubricates the mechanical components of the compressor.

The users of the pneumatic power in the factory should be aware of poisonous leakage but the gas is only the air. The stand alone or smaller system may use the compressed gas which present the hazard of asphyxiation like the nitrogen.

Whenever any type of the compressed gas but not air is used, it presents asphyxiation risk. The compressed oxygen may not lead to asphyxiation but it cannot be used in the devices that are pneumatic powered since they may cause the fire and they are expensive while it does not have any other advantage of the air normally used.

Small vehicles or small pneumatic tools may use carbon dioxide since the containers which were used to hold the fire extinguisher and soda stream are already in place.

The phase change that exists between the gas and the liquid may make it possible to get enough gas in a small container. When carbon dioxide is used, the user should be aware that it is asphyxiant and it may cause freezing problems if it is not vented in the proper way. The hydraulic and pneumatic uses the same application which is fluid power.

The pneumatic uses a compressible gas like suitable pure gas and air but the hydraulic uses incomprehensible liquid media like oil. There are industrial pneumatic applications that use the pressure of more than 80 pounds per square inch.

The hydraulic application may achieve around 5000 psi but the specialized application can reach to 10,000psi. The advantage of the pneumatic is that it is easy to control and to design. The machines are designed easily and they use the standard cylinders with few other components.

They work only by the use of the control which turns the system on and off. The pneumatic system lasts longer and they do not require too much maintenance. Since the gas can be compressed easily, the equipment is not subjected on shock damage.

Gas is capable of absorbing too much force while the fluids in the hydraulic may transfer the force directly. The compressed gas is easily stores and the machine may continue to run even when there is no power. The pneumatic does not cause too much fire risks compared on the hydraulic oil. The new machine does not lead to the overload.

Advantages of using pressured air

- The air is an important part for the pneumatic system and the air is available in the entire world around us and it is not limited to the place or to time.

- Easy to channel: the air is the substance which can pass easily or it can move from a place to another by using small pipe.Flexible temperature: the air may be flexible on different temperature as required. Even if the equipment may have been designed to be used for some circumstances, even when there is extreme condition, air continues to work well.

- Safe: air is loaded in a safe manner, it is not flammable and it cannot lead to the short circuit or it does not explode.The air protects against the two things, contrary to the electrical system which can lead to the fires.

- Clean: air used is clean and there is no chemical used that can be harmful. It may also be cleaned using some cheap process if it is not clean.

This is why pneumatic system is safe to pharmaceutical, textiles, and beverage and food industries.

However pneumatic system also has some disadvantages

- It requires the installation of the air producing equipment: the compressed air has to be prepared so that it meets the requirements.There are some criteria like clean and dry and the necessary lubricant to use in the pneumatic equipment.This is why the installation of some pneumatic system may be expansive like regulator, dryer, lube tube, air filter and compressor.

- The air leaks easily: the properties of the pressurized air include being able to occupy any empty space. To maintain the air pressure is a hard work. There is always a need to seal so that the air cannot leak.When there is a seal leakage, it will lead to the loss of the energy. The pneumatic equipment has to be airtight so that the air that leaks within the system is minimized.

- Noise: when the pneumatic uses the open system, it means that the air will get thrown out of a system.The air is going to come out loud and it will lead to the noise mostly in exhaust tracts. To solve this problem, each dump line is going to have a silencer.

- Easy to be condensed: when the air is under pressure, it can be condensed easily and it needs to be processed first so that it can meet new requirements like being dry, the right pressure or the lubricants have to be added so that the friction may be reduced in the actuators and valves.

1 comments On Basic Information on Pneumatic Systems

Having the right pneumatic fittings can break and upgrade your system. This is great information